The chilling reality of a ground beef recall casts a shadow over our kitchens, raising critical questions about food safety and the steps we can take to protect ourselves and our families. From the farm to our tables, a complex chain of events can lead to contamination, underscoring the need for vigilance and proactive measures. This journey explores the causes of these recalls, the crucial signs of contaminated meat, and the vital preventative steps we can all take to ensure our food is safe and wholesome. We’ll examine the roles of producers, regulators, and consumers in this shared responsibility, aiming to empower you with knowledge and confidence in your food choices.

Understanding the sources of contamination, such as E. coli and Salmonella, is paramount. We’ll delve into the processing failures that can contribute to these outbreaks, exploring visual cues that signal potential danger. Furthermore, we’ll cover safe handling practices, proper storage, and thorough cooking techniques, transforming your kitchen into a safe haven from foodborne illnesses. The discussion extends beyond the consumer, encompassing the crucial role of producers and government agencies in maintaining rigorous safety standards and ensuring the effectiveness of recall processes.

Ground Beef Recall Causes

The unsettling specter of ground beef recalls casts a long shadow over our dinner tables, a stark reminder of the fragility of our food supply chain. Understanding the root causes of these recalls is crucial not only for consumer safety but also for fostering a more resilient and transparent food production system. These recalls, while infrequent relative to the sheer volume of ground beef consumed, highlight critical vulnerabilities in the process, from farm to fork.

Contamination, the silent villain in this story, is the primary driver behind most ground beef recalls. This contamination can occur at various points along the beef’s journey, from the initial stages of animal husbandry to the final packaging and distribution. The sources are multifaceted, encompassing everything from the animal itself to the processing environment and even human error.

Bacterial Contamination Sources

Bacterial contamination is the most prevalent cause of ground beef recalls. Several pathogenic bacteria, particularly Escherichia coli (E. coli) and Salmonella, pose significant health risks. E. coli, often found in the intestines of cattle, can contaminate the meat during slaughter if proper hygiene protocols aren’t strictly followed. Salmonella, similarly prevalent in the animal’s gut, can also transfer to the meat during processing. The severity of illness caused by these bacteria varies, ranging from mild discomfort to life-threatening complications, particularly in vulnerable populations like young children and the elderly. These bacteria are tenacious survivors, able to persist in contaminated environments, even at refrigeration temperatures.

Processing Failures Leading to Contamination

Processing failures represent another crucial pathway for contamination. Inadequate sanitation of equipment, cross-contamination between raw and cooked products, and insufficient cooking temperatures all contribute to the risk. For example, a failure to properly clean and sanitize grinders can lead to the spread of bacteria from one batch of beef to another. Similarly, improper handling of the ground beef after grinding, such as insufficient chilling, can accelerate bacterial growth, increasing the risk of contamination. Even minor lapses in hygiene can have devastating consequences, highlighting the need for rigorous adherence to safety standards at every stage of processing.

Types of Bacterial Contamination and Their Impact

The following table compares different types of bacterial contamination commonly associated with ground beef recalls, highlighting their symptoms and typical treatment approaches.

| Bacteria | Symptoms | Treatment | Notes |

|---|---|---|---|

| E. coli O157:H7 | Diarrhea (often bloody), stomach cramps, vomiting, fever. Severe cases can lead to hemolytic uremic syndrome (HUS). | Supportive care (rehydration, pain management). Antibiotics are generally not recommended unless complications arise. | This strain is particularly dangerous due to its potential for severe complications. |

| Salmonella | Diarrhea, fever, abdominal cramps, nausea, vomiting. | Supportive care (rehydration). Antibiotics may be considered in severe cases or for high-risk individuals. | Symptoms typically appear 6-72 hours after exposure. |

| Listeria monocytogenes | Flu-like symptoms, such as fever, muscle aches, and fatigue. Can cause severe illness in pregnant women, newborns, older adults, and those with weakened immune systems. | Antibiotic treatment is usually necessary. | Can cause meningitis and septicemia in severe cases. |

| Campylobacter | Diarrhea (often bloody), fever, abdominal cramps, nausea, vomiting. | Supportive care (rehydration). Antibiotics may be considered in severe cases. | Often self-limiting, but can be severe in vulnerable populations. |

Identifying Contaminated Ground Beef

The journey from farm to fork is a delicate dance, and ensuring the safety of our food requires vigilance. While recalls are rare, understanding how to identify potentially contaminated ground beef is a crucial step in protecting your family’s well-being. This knowledge empowers you to make informed choices and safeguard your health.

Knowing what to look for in potentially contaminated ground beef is the first line of defense. A keen eye and a cautious approach can significantly reduce the risk of foodborne illness.

Visual Indicators of Contaminated Ground Beef

The appearance of your ground beef can offer valuable clues. While not every visual abnormality indicates contamination, changes in color, odor, and texture warrant careful attention. Discoloration, particularly a greenish or brownish hue, can suggest spoilage. An unusually strong or sour odor is another red flag. A slimy or sticky texture, rather than the expected slightly moist consistency, is also cause for concern. Remember, however, that these indicators are not definitive; further investigation is necessary.

Checking Packaging for Recall Information

The packaging is your primary source of information. Before even opening the package, carefully examine it for any recall notices or labels. These notices are usually prominently displayed, often with bold lettering and clear instructions. Check the product code and lot number on your package and compare them to any recall information available online or through the manufacturer. Pay close attention to any stickers or markings added after the initial packaging.

Importance of Checking “Sell-By” and “Use-By” Dates

“Sell-by” and “Use-by” dates are not arbitrary numbers; they are crucial indicators of food freshness and safety. The “sell-by” date is a guideline for retailers, indicating when the product should be removed from shelves. The “Use-by” date, on the other hand, is a recommendation for consumers, signifying when the product is likely to be at its peak quality and safety. While food might still be safe to consume after the “Use-by” date, it is always best to err on the side of caution, particularly with perishable items like ground beef. Refrigeration significantly impacts the shelf life, so always check the date considering how long the beef has been in your refrigerator.

Infographic: Steps to Take If You Suspect Ground Beef Contamination

Imagine a simple infographic with three distinct panels. The first panel shows a close-up image of a package of ground beef with clearly visible discoloration and a strong odor emanating from it. The caption below reads, “Suspect Contamination?” The second panel illustrates a person carefully checking the packaging for a recall notice and comparing the product code to an online recall list on their phone. The caption reads, “Check for Recalls.” The third panel depicts a person securely disposing of the ground beef in a sealed plastic bag, then washing their hands thoroughly. The caption reads, “Discard & Wash Hands.” The infographic concludes with a contact number for a relevant food safety authority.

Prevention Measures for Consumers

Taking control of your kitchen is the first step towards a safer, healthier life. Protecting yourself and your family from foodborne illnesses associated with ground beef recalls starts with understanding and diligently practicing safe food handling techniques. These practices aren’t just about following rules; they’re about empowering you to make informed choices that safeguard your well-being.

Safe food handling practices are the cornerstone of preventing contamination. By implementing these measures, you create a protective barrier against harmful bacteria and reduce the risk of illness. These practices are not complex, but their consistent application is crucial.

Safe Food Handling Practices

A proactive approach to food safety is paramount. These practices, when followed consistently, minimize the chances of ground beef contamination. Remember, diligence is your best ally in the kitchen.

- Wash your hands thoroughly with soap and water for at least 20 seconds before and after handling raw ground beef, and after touching any surfaces that have come into contact with it.

- Keep raw ground beef separate from other foods. Use separate cutting boards and utensils for raw meat to prevent cross-contamination.

- Clean and sanitize all surfaces, including countertops, cutting boards, and utensils, that have come into contact with raw ground beef with hot, soapy water, followed by a sanitizing solution.

- Avoid washing raw ground beef. Washing raw meat can spread bacteria to other areas of your kitchen.

- Cook ground beef to an internal temperature of 160°F (71°C) to ensure that harmful bacteria are eliminated. Use a food thermometer to check the temperature in the thickest part of the patty.

Proper Storage Temperatures for Raw Ground Beef

The temperature at which you store raw ground beef significantly impacts its safety and shelf life. Maintaining the correct temperature is a crucial step in preventing bacterial growth.

Raw ground beef should be refrigerated at a temperature of 40°F (4°C) or below. Ground beef should be used within 1 to 2 days of purchase. Never leave ground beef at room temperature for more than two hours.

Importance of Thorough Cooking

Thorough cooking is the most effective way to eliminate harmful bacteria, such as E. coli and Salmonella, which can be present in raw ground beef. This is not merely a suggestion; it’s a critical step for food safety.

Undercooked ground beef poses a significant risk of foodborne illness. Using a food thermometer to ensure that the internal temperature reaches 160°F (71°C) is the only reliable way to guarantee that the beef is safe to eat. Visually inspecting the meat is insufficient.

Safely Thawing Frozen Ground Beef

Thawing frozen ground beef correctly is essential to prevent bacterial growth. Improper thawing can create a breeding ground for harmful bacteria, leading to foodborne illnesses.

- Refrigerator Thawing: This is the safest method. Place the frozen ground beef in the refrigerator and allow it to thaw slowly. Plan ahead, as this method can take several hours or even overnight, depending on the size of the package.

- Cold Water Thawing: Place the frozen ground beef in a leak-proof bag and submerge it in cold water. Change the water every 30 minutes to ensure it remains cold. This method is faster than refrigerator thawing but still requires careful monitoring.

- Microwave Thawing: Your microwave may have a defrost setting. Follow the manufacturer’s instructions carefully. Cook the ground beef immediately after thawing using this method.

- Never thaw ground beef at room temperature. This allows bacteria to multiply rapidly, increasing the risk of foodborne illness.

Prevention Measures for Producers

The safety of our food is a shared responsibility, and producers play a pivotal role in ensuring that ground beef reaches our tables free from harmful bacteria. Proactive measures, stringent sanitation, and rigorous quality control are not merely best practices; they are the cornerstones of a safe and reliable food supply. These measures represent a commitment to public health and consumer trust.

Sanitation procedures in beef processing plants are meticulously designed to minimize contamination at every stage, from the moment the animal enters the facility to the final packaging of the ground beef. These procedures are not static; they are constantly evolving and improving in response to technological advancements and emerging scientific understanding of foodborne pathogens.

Sanitation Procedures in Beef Processing Plants

Stringent sanitation protocols are implemented throughout the beef processing plant, employing a multi-pronged approach. This includes thorough cleaning and sanitizing of all equipment and surfaces, using approved detergents and sanitizers. The environment itself is carefully controlled to minimize the presence of bacteria. Regular inspections and audits ensure that these procedures are consistently followed and that any deviations are promptly addressed. Employee hygiene is also a critical component, with strict handwashing protocols and the use of protective clothing mandated to prevent cross-contamination. Regular testing of environmental samples helps monitor the effectiveness of these sanitation procedures and identify any potential issues early on. Effective pest control measures are also implemented to prevent the introduction and spread of pests that can carry bacteria.

The Role of Quality Control Measures in Preventing Contamination

Quality control measures are the vigilant eyes and hands that safeguard against contamination throughout the beef production process. These measures begin with the careful selection and inspection of animals prior to slaughter, ensuring they are healthy and free from disease. Throughout processing, regular testing is performed to detect the presence of harmful bacteria such as E. coli and Salmonella. This testing utilizes various methods, from traditional culture techniques to more advanced molecular methods, allowing for rapid and accurate detection. Traceability systems are implemented to track the movement of beef products throughout the entire process, enabling rapid identification and removal of any contaminated batches. Continuous monitoring of critical control points, such as grinding and packaging, helps to ensure that processes are consistently meeting safety standards. Regular employee training and competency assessments are critical to maintaining high quality control standards.

Comparison of Bacterial Testing Methods in Ground Beef Production

Several methods are employed for bacterial testing in ground beef production. Traditional culture methods involve growing bacteria on nutrient-rich media, allowing for identification and quantification. While effective, this method can be time-consuming. More rapid methods, such as enzyme-linked immunosorbent assays (ELISAs) and polymerase chain reaction (PCR) techniques, offer quicker results and increased sensitivity. ELISAs detect specific bacterial antigens, while PCR amplifies bacterial DNA, allowing for the detection of even small numbers of bacteria. The choice of method depends on factors such as the required speed of results, sensitivity, and cost. Many producers utilize a combination of methods to achieve the highest level of accuracy and efficiency.

Beef Production Process Flowchart

This image depicts a flowchart illustrating the beef production process. The flowchart begins with “Animal Selection and Inspection,” followed by “Slaughter and Carcass Processing,” then “Grinding and Mixing,” and finally “Packaging and Distribution.” Each stage includes a highlighted “Critical Control Point” indicating areas requiring particular attention for sanitation and quality control, such as temperature monitoring, metal detection, and sanitation procedures. The flowchart clearly illustrates the continuous monitoring and checks needed at each stage to minimize the risk of contamination. The final stage, “Distribution,” is linked back to “Quality Control Monitoring” which is a continuous feedback loop that helps improve future production processes.

Government Regulations and Oversight

The safety of our food supply is a cornerstone of public health, and ground beef, a dietary staple for many, demands stringent oversight. Government agencies play a crucial role in ensuring that the meat we consume is safe and free from harmful contaminants. Their responsibilities extend from farm to table, encompassing every stage of production and distribution.

The process of regulating ground beef safety involves a complex interplay of inspections, testing, and enforcement. This intricate system aims to minimize the risk of contamination and quickly address any issues that arise.

The Role of the USDA in Ground Beef Safety

The United States Department of Agriculture (USDA), specifically the Food Safety and Inspection Service (FSIS), is the primary agency responsible for overseeing the safety of meat and poultry products in the United States. The FSIS conducts routine inspections at federally inspected slaughterhouses and processing plants, monitoring sanitation practices, ensuring proper handling of meat, and verifying compliance with safety regulations. These inspections are crucial in preventing contamination at the source. They also establish and enforce regulations regarding labeling, transportation, and storage of ground beef, further mitigating the risk of contamination throughout the supply chain. The FSIS utilizes a Hazard Analysis and Critical Control Points (HACCP) system, a preventative approach to food safety, which identifies potential hazards and implements controls to minimize or eliminate them.

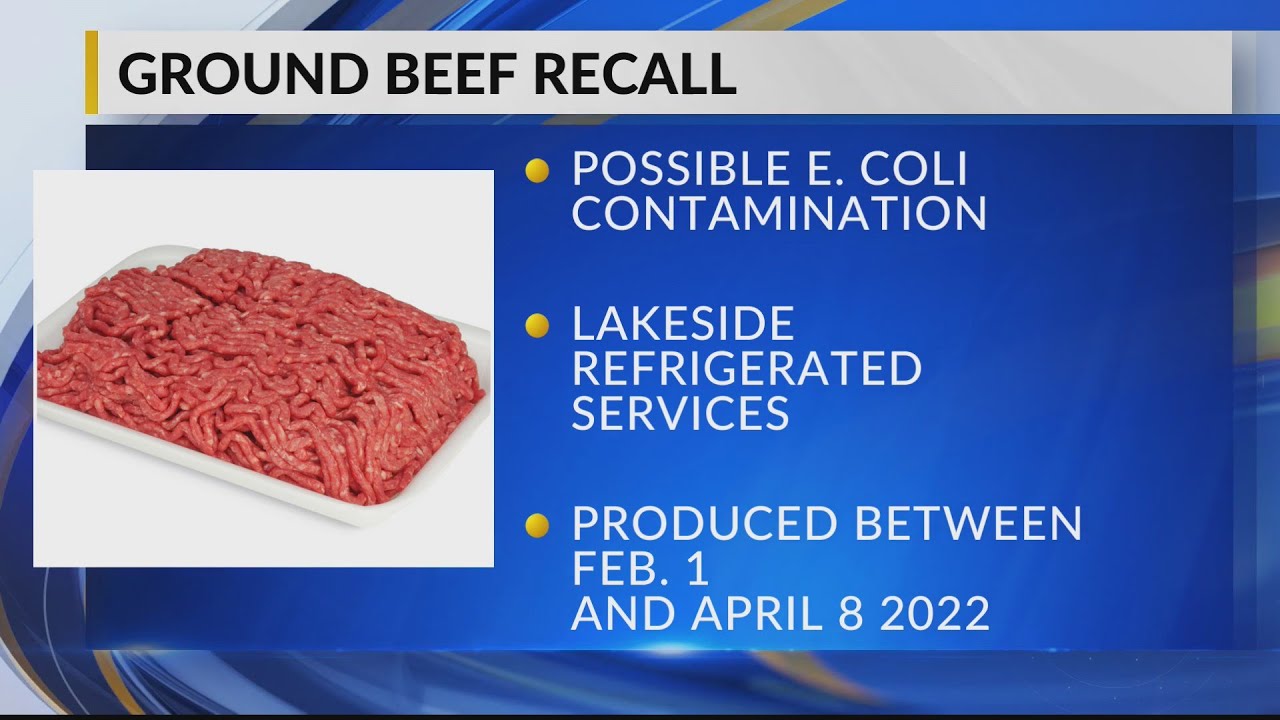

The Ground Beef Recall Process

When contamination is detected, the recall process is swiftly initiated. This process involves identifying the affected products, tracing their distribution, and notifying consumers and retailers to remove the contaminated product from the market. The FSIS works closely with producers and distributors to ensure the effectiveness of the recall, coordinating communication strategies and monitoring the removal of the affected products. The speed and efficiency of this process are critical in limiting the potential impact on public health. Recalls are often categorized by Class I, II, or III, depending on the severity of the health risk posed by the contaminated product. A Class I recall signifies a high risk of serious health consequences or death.

Effectiveness of Current Regulations and Areas for Improvement

While current regulations have significantly improved ground beef safety over the years, they are not without room for improvement. The effectiveness of these regulations is demonstrably tied to the rigorousness of enforcement and the level of industry compliance. Challenges include the difficulty in tracing contamination to its origin, particularly with complex supply chains, and ensuring consistent implementation of safety protocols across all producers. Improvements could include increased investment in technology for enhanced traceability, more stringent penalties for non-compliance, and greater emphasis on proactive measures to prevent contamination rather than simply reacting to outbreaks. Furthermore, strengthening international collaboration to harmonize safety standards across borders could significantly enhance global food safety.

International Comparison of Ground Beef Regulations

| Country | Regulatory Agency | Key Regulations | Enforcement Mechanisms |

|---|---|---|---|

| United States | USDA-FSIS | HACCP, inspection of slaughterhouses and processing plants, labeling requirements | Inspections, recalls, fines, criminal prosecution |

| Canada | Canadian Food Inspection Agency (CFIA) | Similar to USDA, emphasis on traceability | Inspections, recalls, fines |

| European Union | Various national agencies under EU framework | Strict hygiene standards, traceability requirements, residue limits | Inspections, recalls, sanctions |

| Australia | Food Standards Australia New Zealand (FSANZ) | Focus on risk management, food safety standards code | Inspections, recalls, enforcement actions |

Ultimately, safeguarding ourselves from the dangers of contaminated ground beef is a collective endeavor. From the meticulous practices of producers and the vigilant oversight of regulatory bodies to the informed choices and responsible handling of consumers, every link in the chain plays a vital role. By understanding the causes of recalls, recognizing the warning signs, and diligently following safe food handling procedures, we can significantly reduce the risk of foodborne illness and build a stronger foundation for food safety. Empowered with knowledge, we can navigate the complexities of ground beef recalls with confidence and protect the health and well-being of ourselves and our communities.

Their journey began with a spark, a shared dream on the field. To understand the raw numbers behind Nitish Kumar Reddy and Harshit Rana’s impressive debut, check out the detailed statistics of Nitish Kumar Reddy and Harshit Rana’s debut. A deeper dive into their performance reveals a captivating narrative; a Nitish Kumar Reddy and Harshit Rana India debut performance review showcases their potential.

Meanwhile, across the Atlantic, the world of basketball buzzes with the drama surrounding James Harden; the Philadelphia 76ers James Harden trade speculation and analysis keeps fans on the edge of their seats, a testament to the unpredictable nature of sporting success.